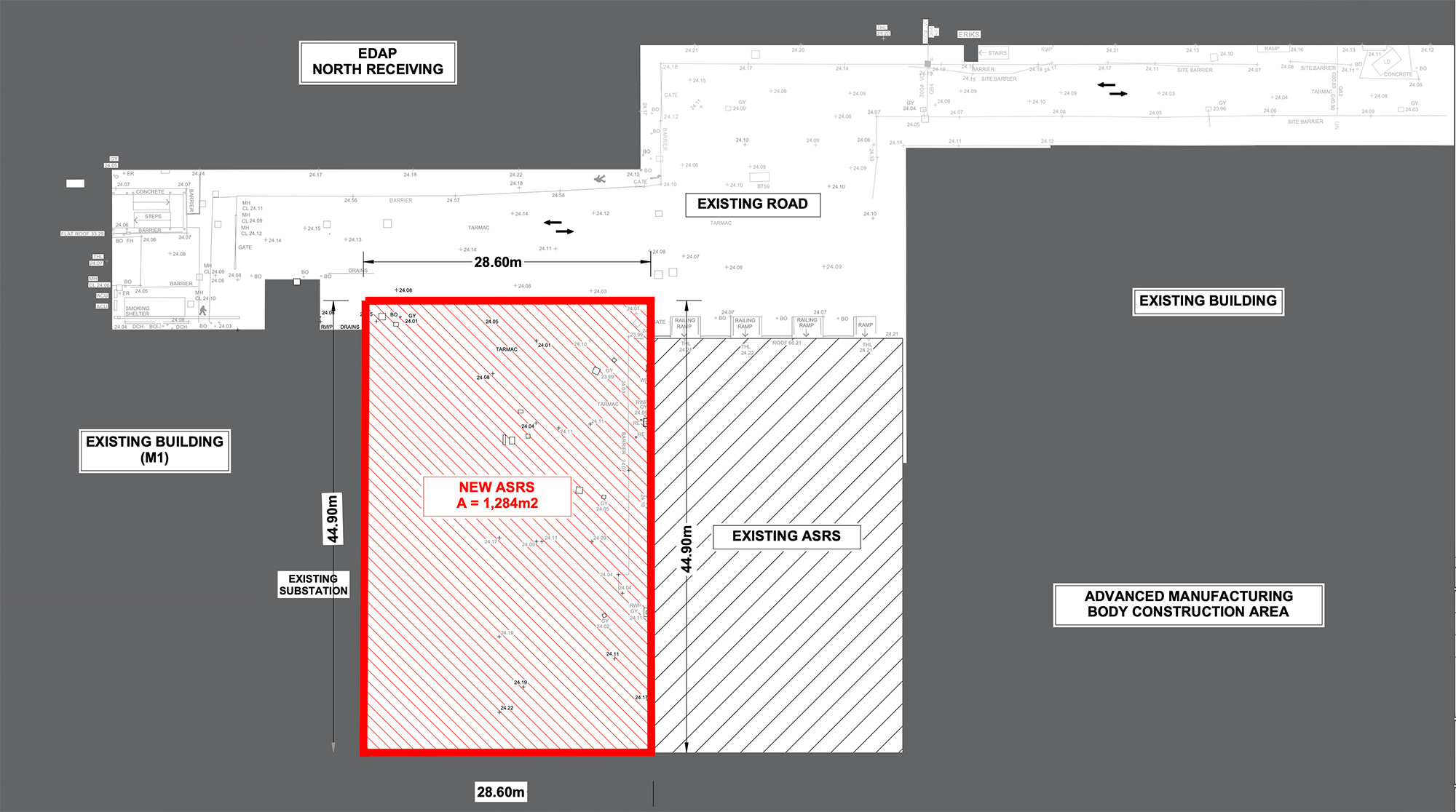

JLR is seeking to put up a building measuring almost 1,300 square metres on its Halewood site as it looks to increase production capacity.

The manufacturer, which is shifting towards producing all-electric vehicles at the Merseyside factory, has lodged a planning application with Knowsley Council for an automated storage and retrieval system (ASRS) building next to the current one.

According to the plan, it’ll be used to store incoming car bodies before they’re sequenced and moved to the production line via cranes, said the Liverpool Echo.

The ASRS will be 28.8m in height, take up 1,284 square metres of floorspace and boast totally automated storage.

Manchester-based planning agent WSP said there wouldn’t be any alterations to existing parking or road layouts, nor would there be an increase in the workforce or deliveries.

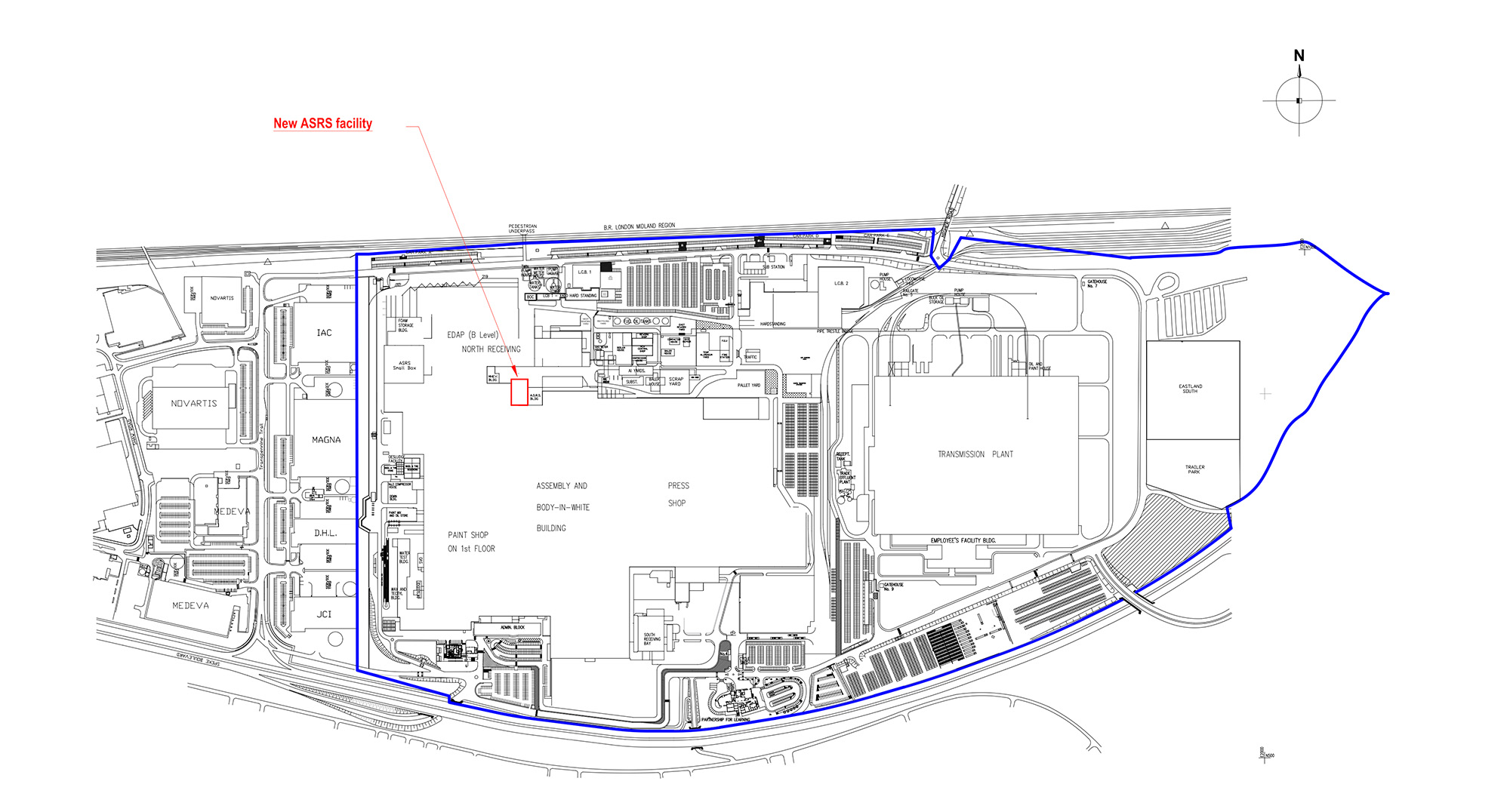

The location of the proposed building, taken from the planning, design and access statement. The blue line shows JLR’s land ownership boundary and the red line shows the application site boundary. Image: WSP

It said the development would improve efficiency at the plant, and urged the council to approve it without delay since it said it complied with local and national planning policies.

WSP is also seeking retrospective approval for three temporary structures with a canopy, which were put up last October to provide manufacturing and storage space as well as associated works, for five years.

The site previously housed three temporary tent structures covering 3,210 square metres that were taken down in early 2022 and which helped with material planning and logistics operations, providing manufacturing and storage space.

The planning decisions are expected in early November.

In April, JLR announced it would be investing £15bn over five years in its industrial footprint, vehicle programmes, autonomous, AI and digital tech as well as people skills, with Halewood singled out to become an all-electric manufacturing plant.

JLR employs some 3,700 people directly at Halewood, supporting a further 1,000 people indirectly via its suppliers and contractors.

Pictured at top via PA is a stock image of the Halewood plant