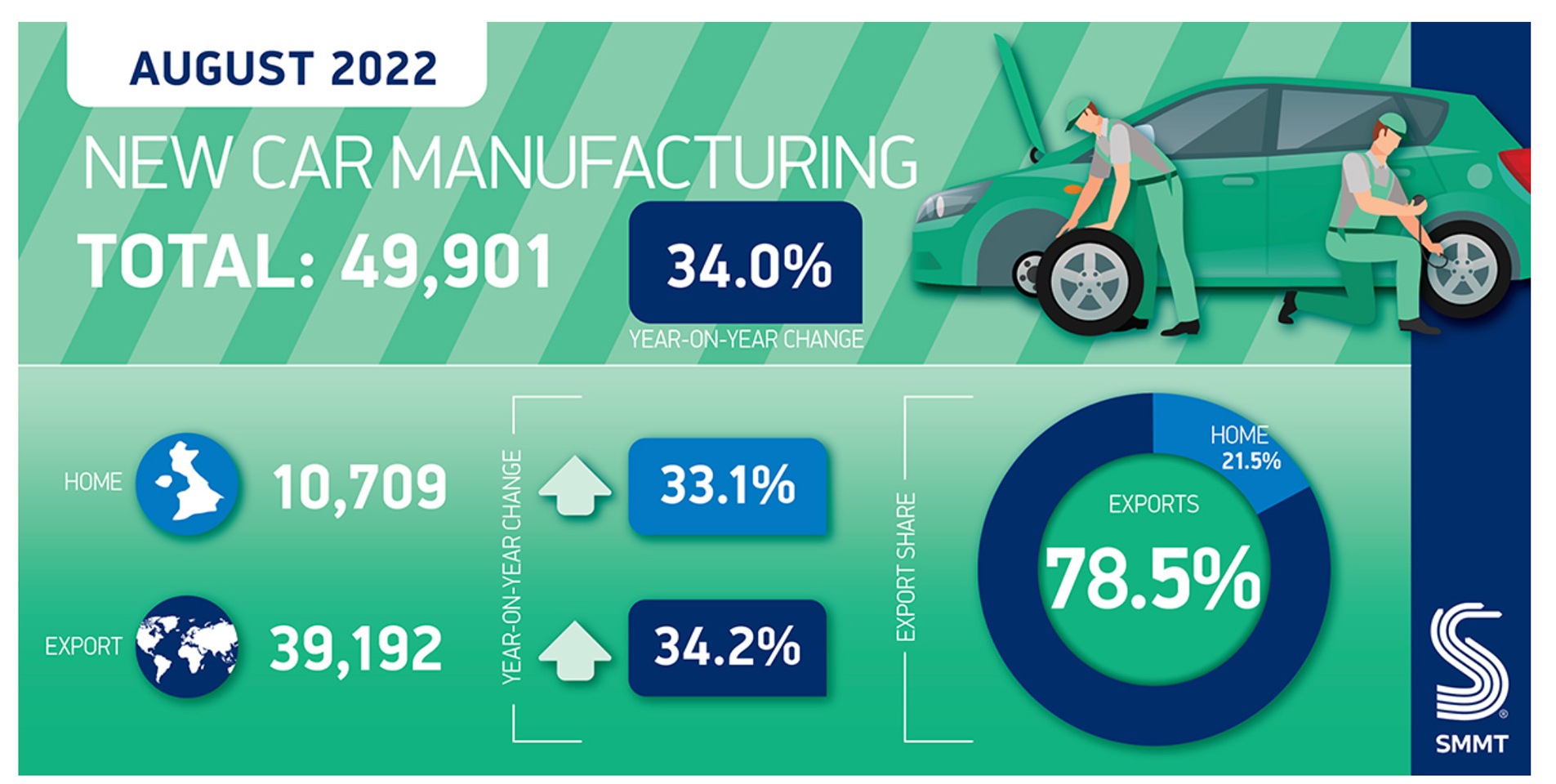

UK car manufacturing increased for the fourth consecutive month in August, rising 34 per cent year on year to 49,901 units, according to the latest figures published today by the SMMT.

However, the performance was still a massive 45.9 per cent below August 2019’s pre-pandemic level of 92,158 units, which the SMMT said underlined the scale of recovery still needed.

It follows a very weak performance in August last year when production stoppages and extended shutdowns caused by the global chip shortage saw figures plummet to a historic low of 25,736 units – the lowest-volume August since 1956.

This year, output for domestic sales increased by 33.1 per cent in August to 10,709 units, while the number of cars built for export rose by 34.2 per cent to 39,192 units.

Production of battery-electric (BEV), plug-in hybrid (PHEV) and hybrid (HEV) vehicles also grew.

Almost a third (32.2 per cent) of all cars made in Britain in August were one of these models, equivalent to 16,059 units, with most of them (70.5 per cent) exported.

Output of BEVs alone more than doubled, rising by 115.9 per cent to account for almost one in 10 cars produced.

Year-to-date, however, overall production remains 13.3 per cent down on the first eight months of 2021 at 511,106 units.

Overall, it means that factories have turned out 78,501 fewer cars so far this year, with output more than half a million units behind average pre-Covid volumes of 1,030,527.

The sector is now on course to produce fewer than a million cars for the third consecutive year.

Latest production outlook by AutoAnalysis forecasts 866,000 units for 2022. Output last year was 859,575, while in 2020 it was 920,928. Before that, 1986 was the last year output fell below 1m units.

The figures come as new analysis from SMMT highlights the staggering energy costs, already the highest in Europe, faced by the UK’s automotive vehicle and component manufacturers.

With businesses’ collective energy bill having risen by more than £100m over the past 12 months to more than £300m, the government’s significant intervention to cap prices over winter has temporarily limited further rises.

But with these costs expected to more than double again next year and with some manufacturers anticipating even steeper increases, longer-term solutions need to be found to assure the viability of the sector beyond the end of the cap in six months’ time, said the SMMT.

Mike Hawes, SMMT chief executive, said: ‘While another month of rising UK car production is good news and testament to sectoral efforts to overcome supply chain shortages, it overshadows what is an extremely tough and uncertain environment for manufacturers.

‘Volumes are down dramatically and firms are having to take drastic steps to safeguard their businesses in the face of myriad challenges.

‘The government’s measures announced last week to alleviate crippling energy costs provide valuable respite, but long-term action is needed to restore stability and provide the sector with a globally competitive investment framework.

‘Reform of business rates, enhanced capital allowances, an affordable and secure supply of low-carbon energy, and investment in new skills can enable this critical sector to deliver the economic growth, productivity improvements, balance-of-trade benefits and job security the UK sorely needs.’

What the industry says

Rising energy and supply prices are immediate concern

Growth and investment are a key agenda for the new government and few sectors are set to require investment like the automotive industry in the coming years as it looks to transition towards zero-emissions vehicles.

Rising energy and supply prices are the immediate concern for the industry, and despite recent announcements to reduce cost burdens, more work needs to be done to ensure the sector can continue to grow electric vehicle manufacturing.

A fourth consecutive month of growth is positive news, though overall output remains well below 2021 levels – with rising prices threatening to reverse the past four months of effort.

Employing more than 780,000 people across the country, the automotive sector should be at the forefront for government planners as they work to reverse the current recession.

Jim Holder, editorial director, What Car?

Firms will need ongoing support and investment

While long-term supply chain issues are showing signs of further improvement, it remains an incredibly challenging period for the sector.

It seems that new hurdles are never far away. In the new vehicle market, the weakness of the pound will step up pressure on importers and manufacturers reliant on stock and parts from overseas.

It’s clear that firms across the motor industry will need ongoing support and investment to ensure the momentum of recovery in the face of strong economic headwinds.

Lisa Watson, director of sales, Close Brothers Motor Finance

Passing costs on is getting more challenging

A gradual easing of global supply shortages plus government support on energy costs will aid UK car production in the coming months.

But inflation is driving up input costs, and a weakening pound threatens to do so further.

Passing costs to the consumer is becoming increasingly challenging, although at this stage manufacturers still continue to have busy order books to work their way through.

Richard Peberdy, UK head of automotive, KPMG